Quality

Simultaneously provides the highest quality water possible while maximizing filtration output. Continuous profiling of each filter provides assurance that the filtration process is performing well beyond regulation requirements and provides a more rapid and direct troubleshooting solution when filtration problems occur

Performance

Continuously monitors the water quality and filter condition to ensure optimum performance. As customer demands change, the system adjusts automatically to meet the required flowrates. Automatic backwash sequencing guarantees to prevent damage and ensures the protection of the filtration system, costly mistakes and potential water quality issues.

Efficiency

Calculates the filter efficiency over-time and can advise the system of the suggested parameters. This can extend the life of the filter and reduce operational costs. Efficiency reports are generated to review proper filter operations.

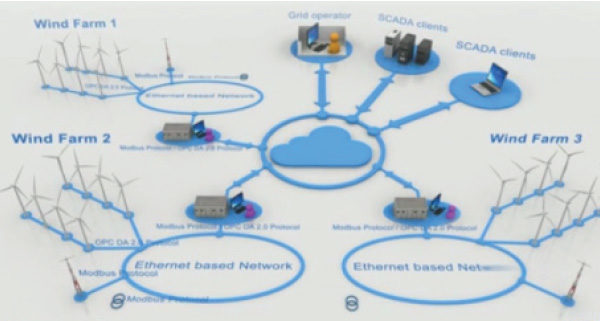

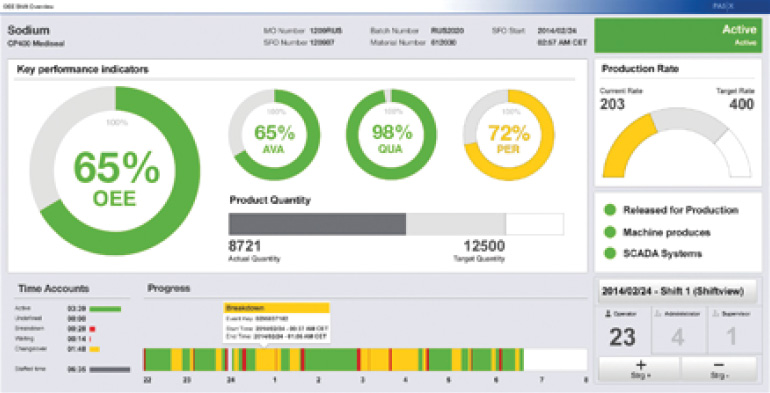

OPEN ARCHITECTURE

Filter Hydronomics can be introduced into any Filter Control System for Water and Waste Water. Filter Hydronomics can be incorporated using leading SCADA packages such as Schneider Electric (Wonderware InTouch and System Platform), GE (Proficy, iFix, Cimplicity), Rockwell Automation (FactorTyTalk ME and SE), along with PLC manufacturers like Schneider Electric (Modicon), Rockwell Automation (Allen Bradley), and Siemens. The open architecture with Filter Hydronomics allows for integration into existing systems and present the controls in a unified interface.

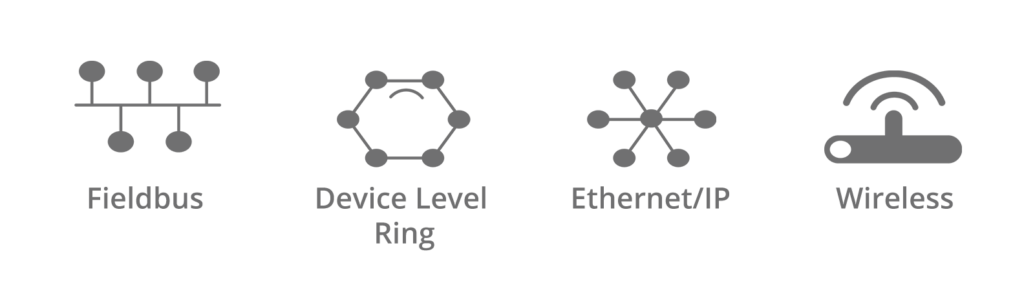

UNIFIED NETWORK

Filter Hydronomics incorporates ethernet based valve actuators to provide a unified network for simple administration and maintenance. This allows the actuators to share the same network as the plant wide Ethernet Network and benefit from economies of scale to reduce implementation costs. Filter Hydronomics can be applied to any industrial ethernet protocol, allowing communication to multiple hosts simultaneously and increased data rates – all being major benefits versus Field Bus protocols

CENTRALIZED CONTROL

Filter Hydronomics is easily selected and controlled from Remote Mobile Terminals (RMTs) utilizing its technology to synchronize and visually display display instantaneous changes throughout the system. RMTs can be temporarily housed in localized, free-standing modular pedestals to reduce capital expensitures and provide rapid replacement, while still delivering visual controls for maintenance and service.

AVAILABILITY

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id

Why Filter Hydronomics

• Easier connection to a variety of host systems

• Instantly familiar to anyone with ethernet

• Quality of service to prioritize network traffic

• Provides better security

• Provides an adaptive and intuitive control system to meet the demands of your filter control system

• Includes a comprehensive filter control scheme to give you peace of mind

• Keeps a constant watch on the essential filter parameters and assists you in all aspects of the filtering process

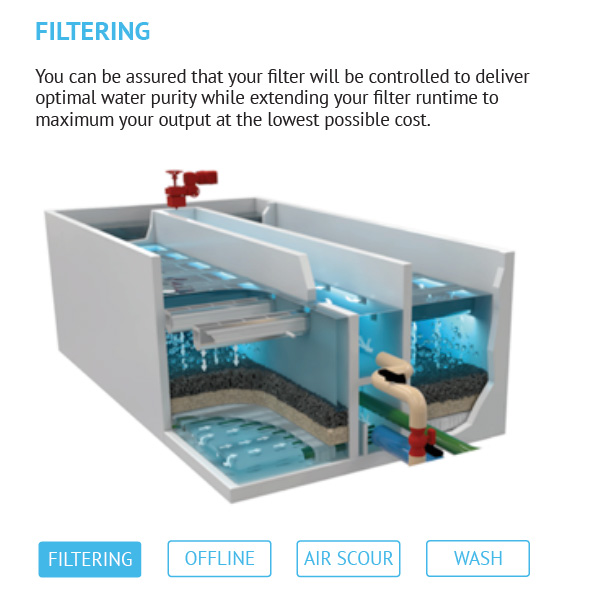

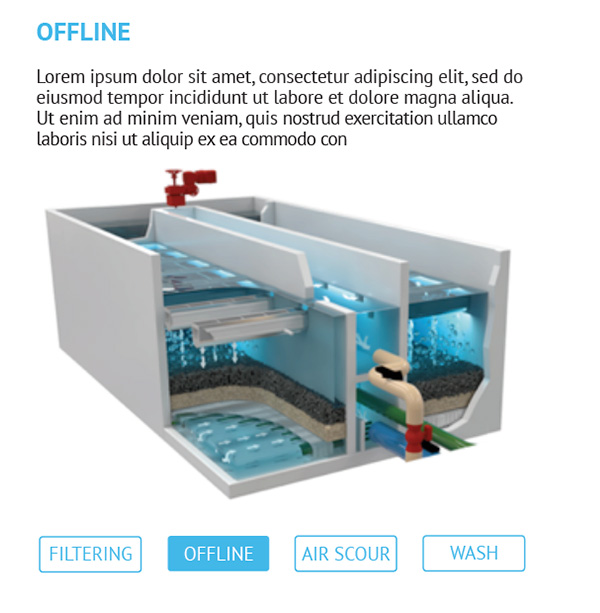

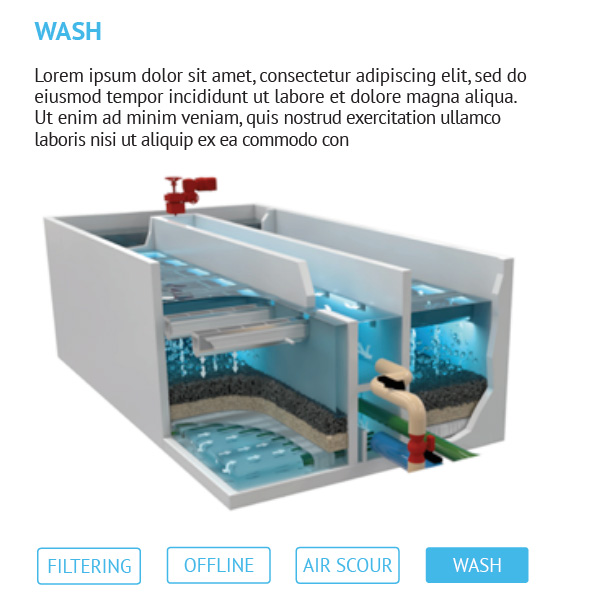

• You can be assured that your filter will be maintained to deliver optimal runtime to maximize your output at the lowest possible cost

How It Works

Filter Hydronomics’ centralized control, economizes (maximizes filtration efficiency) operation by monitoring all filters and strategically scheduling backwashes, while meeting demand.

Predictive filtration problems can be predicted and detected utilizing collected real-time and historical data analysis. Additional methods such as rate-of-change examination, in conjunction with regulatory body requirements, allows notifications and recommendations to prevent filter breakthrough.

Major and minor event detection allows instant determinations and prevent unnecessary backwash initiation. Visual profiling events assist in these determinations to extend the filter run-time to its full potential.

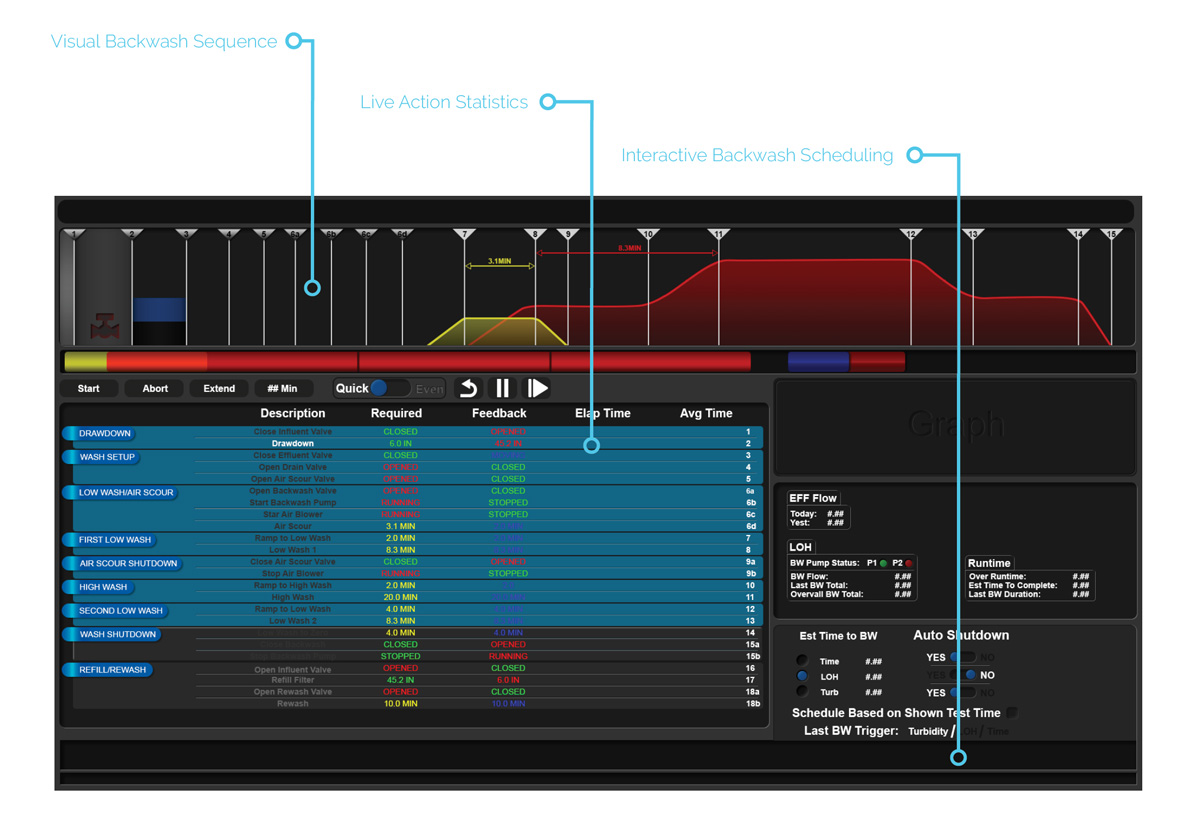

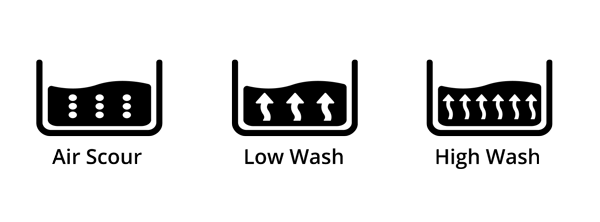

Visual Sequence

Backwash profiling keeps you one step ahead.

Extend the life of your filters. With interactive visualization, you can take the concept a step further.

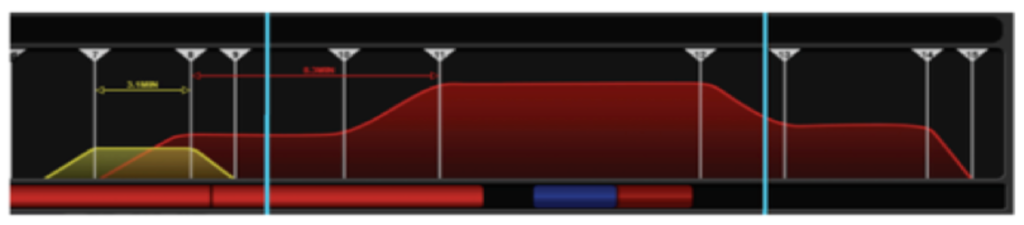

Schedule Timeline

Minimize downtown. Seamless scheduling. All filters operating in unison.

Strategically identify conflicting backwash requirements. Why depend on static backwash schedules? A global plan will ensure while meeting demand.

Unified Network

Open communications. Support any industry-standard protocols.

We let you take advantage of any preferred network or protocol to connect your devices.

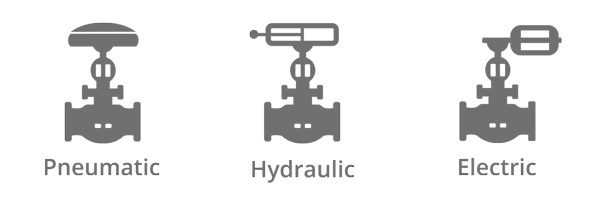

Actuators

Don’t be held back. We can integrate a wide variety of valve types.

Effortlessly incorporate various valve types. We include valve protection logic to reduce unnecessary wear.

Learn how we protect your hardware

Learn how we protect your hardware